Torque remains one of the most important measurement parameters in the manufacturing industry. Recent advances in manufacturing technology are placing increasing importance on the clamping forces necessary in the assembly of products. Current tolerances can no longer be met through the measurement of torque alone, and the measurement of both torque and angle of bolt rotation is now considered critical to the quality of manufactured products.

Furthermore, torque is often used as an input measurement parameter for the calculation of electric motor, water pump, and motor vehicle driveline efficiencies and even plays a role in citizen safety through ensuring that bottle caps of pharmaceutical products cannot easily be unscrewed by young children.

Calibration services are offered on a wide range of Torque Transducers including Square Drive, Flange Type, and Smooth Shaft Transducers. Calibrations can be performed in the range from 50 N·m to 20 kN·m

The Torque Laboratory does not offer a calibration service for Torque Wrenches/Tools.

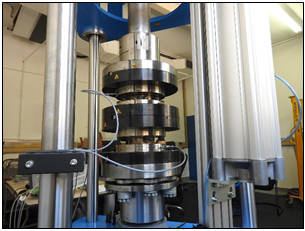

Figure 1: Flange Type Static Torque Transducer being calibrated

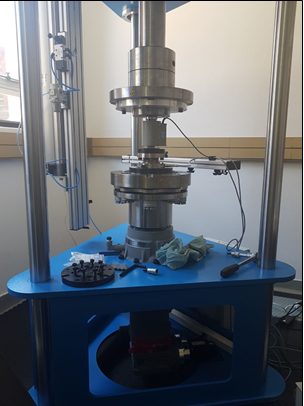

Figure 2: Square Drive Rotary Torque Transducer being calibrated.

Key Facts

After voluntary laboratory suspension due to space constraints and institutional prioritization the torque laboratory now offers improved services in a new laboratory location with new equipment. (See Figure 3 below)

Figure 3: New 20 kN·m Torque Comparator machine

Torque is a derived parameter and obtains its metrological traceability from Force (N) and Length (m) according to equation1 below:

Where:T is generated torque in Newton metres (N·m), F is force in Newtons (N), L is length of the lever in metres (m)

The force is commonly generated by deadweight stacks according to equation 2 below:

Where:F is the generated force in Newtons (N), m is the mass of the weight stack in kilograms (kg), g is the gravitational acceleration constant in metres per second squared (ms-2),

The TCM however, currently imports its metrological traceability from International Metrology Institutes through the overseas calibration of Reference Torque Transducers.

It is envisaged that the Torque Laboratory will have regained SANAS ISO/IEC 17025:2017 accreditation by April 2020. The Torque Laboratory can also perform Calibration of Torque Angle on Transducers which measure the angle as well as torque. The current National Measurement Standards for Torque are three HBM TB2 Torque Transducers namely:

-

HBM TB2/500 N·m (covers range from 50 N·m to 1000 N·m)

-

HBM TB2/3000 N·m (covers range from 500 N·m to 5000 N·m)

-

HBM TB2/10 kN·m (covers the range from 1 kN·m to 20 kN·m)

(See Figure 4 below, left to right:)

Figure 4: Set of Reference Torque Transducers

How we can help you

Torque Transducer Calibration Services

- High Accuracy Square Drive Rotary Torque Transducers,

-

- ,

- High Accuracy Flange Type Static Torque Transducers

- High Accuracy Smooth Shaft Rotary Torque Transducers,

- High Accuracy Smooth Shaft Static Torque Transducers.

- Torque Angle of Rotary Torque Transducers.

Development of National Measurement Standards

Current development work involves the obtaining of ISO/IEC 17025 accreditation and further reduction of measurement uncertainties. An upgraded 1 kN·m deadweight and beam torque rig is in the process of being designed.

The team

Name and Surname

|

Designation |

Emai |

Telephone

|

|

James Matosse

| Undergraduate Bursary: Vacation Work

|

jmatosse@nmisa.org

| +27 12 947 2764

|

Sipho Dlamini

| Scientist: Force, Torque and Hardness

|

sdlamini@nmisa.or |

g

| +27 12 947 2868

|

Events

Technical Advisory Forums (TAFs) are held periodically. Potentially interested parties will be notified by E-mailed invitations.

Contacts

Any more information, contact

James Matosse or email torque@nmisa.org or call +27 12 841-2075